In a fusion of everyday ingenuity and cutting-edge medical technology, South Korean researchers have reimagined the humble hot glue gun as a revolutionary tool for orthopedic surgery.

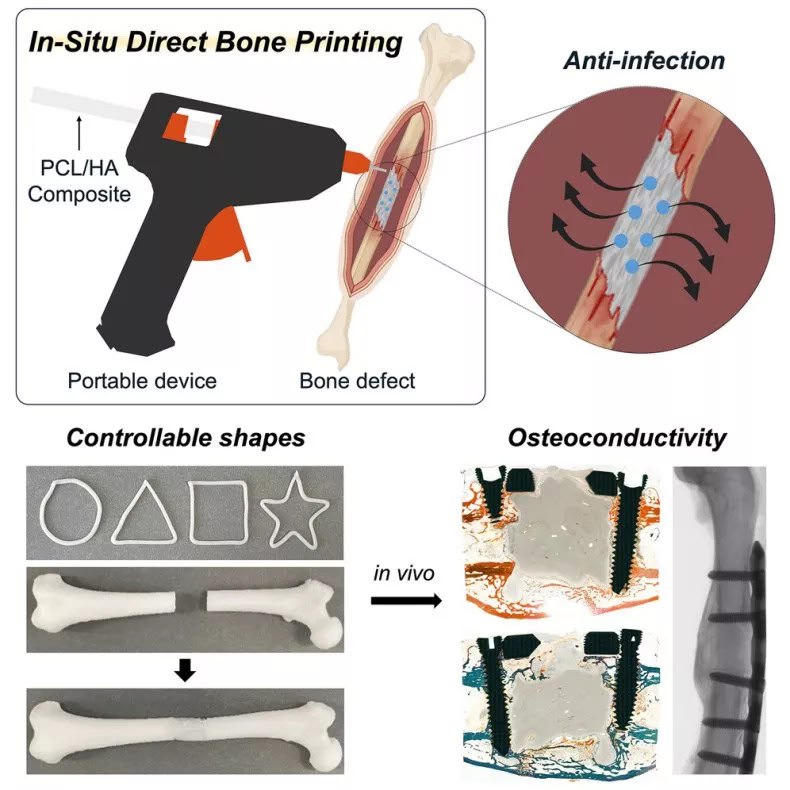

This handheld 3D printer, capable of fabricating customized bone grafts directly onto fractures during operations, promises to slash surgery times, minimize infection risks, and accelerate healing. Tested successfully in animal models, the device could soon redefine how surgeons tackle complex bone injuries, turning operating rooms into on-the-spot fabrication labs.

From Craft Tool to Surgical Savior

The innovation stems from a collaboration between scientists at Sungkyunkwan University in South Korea and researchers from the United States. Traditional bone repair often relies on pre-manufactured implants made from metal, donor bone, or lab-printed materials.

The innovation stems from a collaboration between scientists at Sungkyunkwan University in South Korea and researchers from the United States. Traditional bone repair often relies on pre-manufactured implants made from metal, donor bone, or lab-printed materials.

For irregular fractures — common in trauma cases — these must be custom-designed and produced beforehand, adding delays and costs. The new device flips this script: surgeons load it with a specialized filament, heat it to a tissue-safe temperature, and extrude biodegradable scaffolds right into the defect site.

At its core, the tool is a modified commercial glue gun, compact enough to fit in a surgeon's hand and manually operated for intuitive control. "Because the device is compact and manually operated, the surgeon can adjust the printing direction, angle, and depth during the procedure in real time," explained lead researcher Professor Jeong Sik Lee. This real-time adaptability ensures a perfect fit for jagged breaks, filling gaps that off-the-shelf solutions can't match — all in mere minutes, drastically cutting operative times.

A Biocompatible Filament Packed with Healing Power

The magic lies in the filament: a composite of hydroxyapatite (HA) — a mineral that mimics natural bone and promotes regeneration — and polycaprolactone (PCL), a flexible, biocompatible thermoplastic. By tweaking the HA-to-PCL ratio, the team can tailor the graft's hardness, strength, and degradation rate to suit specific bones, from the rigid femur to more pliable areas.

The magic lies in the filament: a composite of hydroxyapatite (HA) — a mineral that mimics natural bone and promotes regeneration — and polycaprolactone (PCL), a flexible, biocompatible thermoplastic. By tweaking the HA-to-PCL ratio, the team can tailor the graft's hardness, strength, and degradation rate to suit specific bones, from the rigid femur to more pliable areas.

To combat post-surgical infections — a leading cause of implant failure — the filament incorporates antibiotics like vancomycin and gentamicin. In lab tests, these scaffolds effectively halted the growth of common culprits E. coli and S. aureus, both in petri dishes and liquid cultures. The low extrusion temperature (around body heat) further protects surrounding soft tissues from thermal damage, ensuring the graft integrates seamlessly without necrosis.

Promising Results from Rabbit Trials

The device's potential shone in rigorous animal studies on New Zealand white rabbits with critical-sized femoral defects. After implanting the 3D-printed grafts, the team monitored healing over 12 weeks. Results were striking: no infections or tissue damage occurred, and bone regeneration outpaced traditional bone cement by a significant margin. Micro-CT scans revealed robust new bone formation, with the biodegradable scaffold gradually dissolving as natural tissue took over.

"This highlights a significant advantage in terms of reducing operative time and improving procedural efficiency under real surgical conditions," Lee noted. Compared to conventional methods, the approach not only speeds recovery but also reduces reliance on donor grafts or metals, which can trigger immune responses.

Also read:

- Sakana AI Expands into Finance: Japanese Startup Hires Technical Program Manager for Enterprise AI Integration

- Supir: The Revolutionary Image Restorer and Upscaler Redefining AI Restoration

- DeepSeek's New Rules: Mandatory AI Labels Usher in an Era of Content Traceability

Paving the Way for Human Trials

While still in preclinical stages, the researchers are gearing up for human testing, focusing on sterilization protocols, production standardization, and regulatory hurdles. If successful, this "glue gun" could democratize personalized orthopedics, making advanced implants accessible in resource-limited settings. It aligns with broader trends in in situ 3D printing, where fabrication happens at the point of need — think customized wound dressings or vascular scaffolds.

As one collaborator put it, "We believe this approach has the potential to fundamentally change the paradigm of bone defect treatment." For patients with fractures from accidents, osteoporosis, or cancer resections, the implications are profound: faster surgeries, fewer complications, and a quicker return to life unhindered by hardware.

In an era where biofabrication meets bedside urgency, South Korea's glue gun gambit reminds us that sometimes, the simplest modifications yield the most profound breakthroughs.