AI Optimized Warehouse

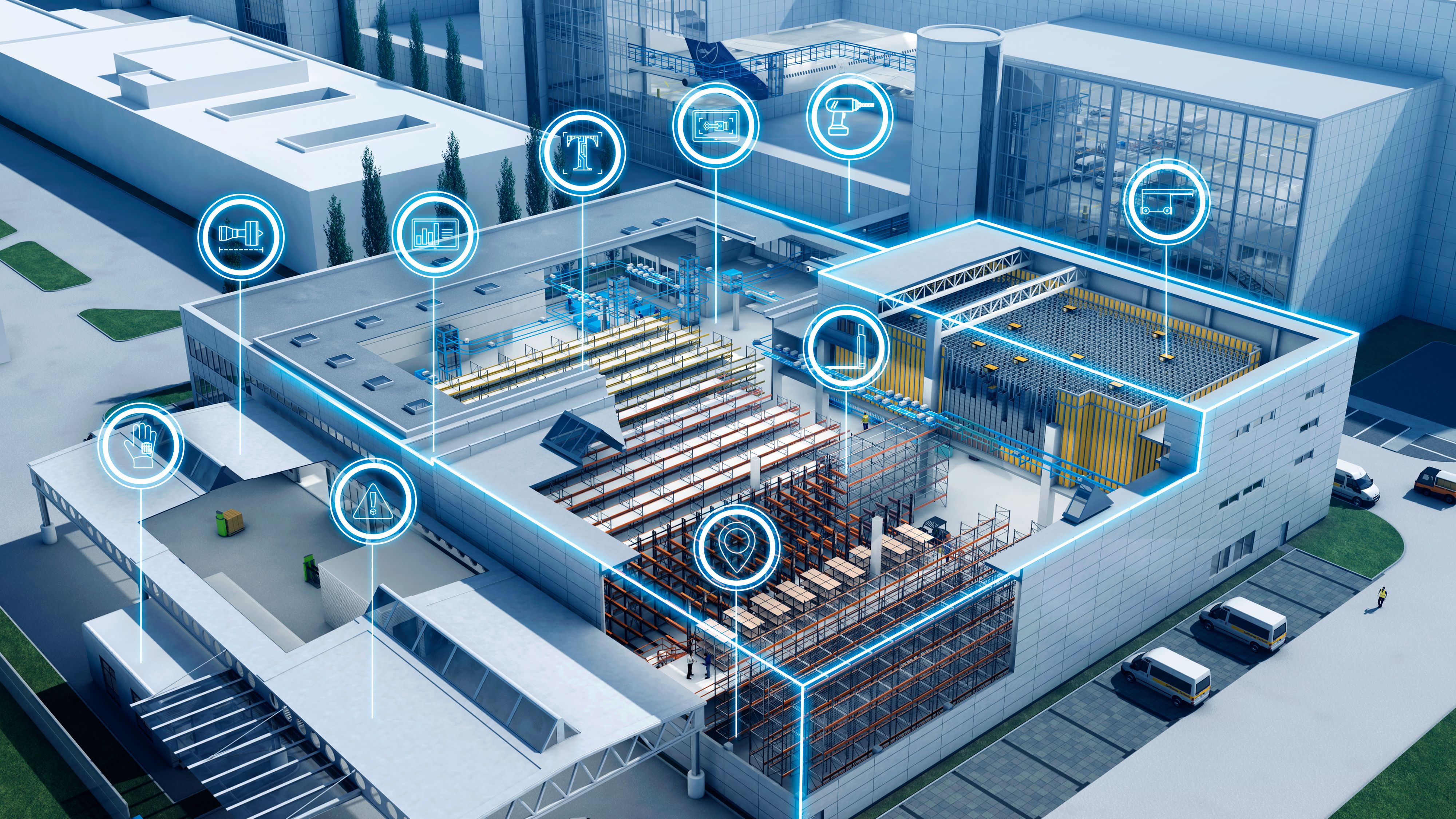

Step into the forefront of logistics innovation with the AI-optimized warehouse. This cutting-edge facility embodies the future of efficient inventory management and distribution.

Envision an environment where human knowledge and machines work seamlessly to maximize accuracy and efficiency. The warehouse can adapt and evolve in real time thanks to the basis of AI technologies like machine learning and predictive analytics.

To guarantee effective and timely product delivery; it continuously analyzes data to predict demand trends, modify storage layouts, and simplify processes.

Apart from being efficient, this warehouse also exemplifies sustainability, it adheres firmly to resource preservation and environmental sustainability, using artificial intelligence (AI) to increase productivity and decrease waste.

Setting a new standard for companies looking to cut expenses, increase productivity, and lessen their environmental effect is this creative storage method. In addition, the definition of logistical operations has changed. Explore how inventive HRM and technology developments may affect warehouse operations in the future.

Understanding the AI-Optimized Warehouse

Components of AI Optimization

Machine Learning: At the heart of the AI-optimized warehouse lies machine learning—a technology enabling systems to learn from data and improve operations without explicit programming.

In this case, algorithms look for trends in the past data to enable the warehouse to make intelligent decisions on its own. With machine learning, the facility can anticipate changes in demand and optimize storage arrangements, among other things. This allows for continual process improvement.

In this case, algorithms look for trends in the past data to enable the warehouse to make intelligent decisions on its own. With machine learning, the facility can anticipate changes in demand and optimize storage arrangements, among other things. This allows for continual process improvement.

Predictive Analytics: Imagine a warehouse that can foresee demand trends and inventory needs before they arise. Predictive analytics can be vital in this situation. Predictive models reduce stockouts and excess inventory by forecasting future requests using historical and current data.

Proactive decision-making is made possible by this foresight, which guarantees that the warehouse is always ready to effectively fulfill orders.

Real-time Adaptability: In the dynamic realm of logistics, adaptability is key. AI-optimized warehouses are highly adaptive in real-time, quickly adapting to changing circumstances.

These facilities use artificial intelligence (AI)-powered systems that react instantly to changes in customer behavior, supply chain interruptions, and demand variations.

Because of its adaptability, the warehouse can adjust worker levels, routes, and inventory distribution as needed to maintain smooth operations even in the face of unanticipated events.

Collaborative Operations: Humans and Machines

Enhancing Productivity: Far from replacing humans, AI in warehouses collaborates with human expertise to amplify productivity.

By automating monotonous operations like inventory tracking and data analysis, artificial intelligence (AI) frees up human resources to focus on higher-value occupations like strategic decision-making and complex problem-solving.

When humans and machines work together, production rises overall and workers become more creative and productive.

Precision in Inventory Management: Inventory management is transformed by the fusion of human insights with AI accuracy. Warehouses can now monitor and organize items with unprecedented levels of precision thanks to AI-driven algorithms.

This accuracy reduces mistakes and guarantees that the appropriate supplies are available when needed, which saves storage space and increases overall operating efficiency.

The Functionality of an AI-Optimized Warehouse

Inventory Management

Tracking and Organization: In an AI-optimized warehouse, tracking and organizing inventory reach unparalleled levels of efficiency. Artificial intelligence (AI) powered systems continuously track each item's journey from delivery to storage and return.

Modern technologies like RFID tagging and barcode scanning are used by these systems to keep an eye on inventories in real time. This makes it easier to discover things, reduces search time, and ensures accurate stock counts.

Modern technologies like RFID tagging and barcode scanning are used by these systems to keep an eye on inventories in real time. This makes it easier to discover things, reduces search time, and ensures accurate stock counts.

The warehouse becomes a smoothly operating machine, with each item being properly accounted for and readily available.

Demand Forecasting: One of the warehouse's superpowers is its ability to predict demand with remarkable accuracy. The warehouse analyzes historical data, industry trends, and even external elements like weather patterns to estimate future demand using complex algorithms.

Because of this foresight, proactive inventory management is made feasible, ensuring that the right quantity of commodities is available when needed. The warehouse anticipates demand and reduces excess inventory to prevent supply shortages, maximize resource efficiency, and increase customer satisfaction.

Order Fulfillment

Streamlining Workflows: AI optimization streamlines the entire ecommerce fulfillment process, orchestrating a symphony of efficiency. Because workflows are well-planned and automated, there are fewer human errors and delays.

Artificial intelligence (AI) algorithms maximize productivity by optimizing picking routes, directing warehouse workers to the exact locations of products, and reducing trip time. Orders are filled accurately and consistently thanks to this simplification, which also speeds up the fulfillment process.

Rapid and Flawless Deliveries: The ultimate goal of an AI-optimized warehouse is to facilitate rapid and flawless deliveries. Orders are processed properly and quickly thanks to a mix of improved workflows and effective inventory management.

The real-time flexibility of AI guarantees prompt resolution of unanticipated issues, hence averting delivery process interruptions. The result? Customers are more satisfied and the warehouse's reputation for dependability is strengthened when their products arrive on time and without any issues.

Benefits Beyond Efficiency

Sustainability Measures

Eco-Friendly Operations: Within the realm of AI-optimized warehouses, sustainability takes center stage. AI is being used by these facilities to create eco-friendly operations and lessen their environmental impact.

All of the parts, such as the energy-efficient lighting and temperature control systems and renewable energy sources, are designed to lower carbon emissions.

All of the parts, such as the energy-efficient lighting and temperature control systems and renewable energy sources, are designed to lower carbon emissions.

Additionally, AI-driven optimization guarantees resource conservation by cutting waste and raising the company's general ecological consciousness.

Resource Conservation: Beyond efficiency, AI actively contributes to resource conservation. To find chances for conservation, artificial intelligence (AI) analyzes data on resource use, including power, water, and material usage.

The warehouse can effectively anticipate resource requirements thanks to predictive analytics, which reduces waste and maximizes utilization.

AI-optimized warehouses prioritize resource conservation, making a positive impact on the environment by, for instance, maximizing the use of packaging materials or consuming less power during off-peak hours.

Cost Reduction and Business Impact

Maximized Efficiency: Efficiency isn’t solely about speed; it’s also about doing more with less. Warehouses with AI optimization are excellent at increasing productivity across the board. These facilities increase production by automating repetitive operations, streamlining procedures, and lowering labor expenses.

Predictive analytics and efficient inventory management not only reduce stockouts and overstocking but also optimize inventory levels and save related expenses. This increased effectiveness boosts overall operational performance and results in considerable cost savings.

Environmental Responsibility: Embracing AI in warehouse operations isn’t just about efficiency and cost reduction; it’s about assuming environmental responsibility.

Companies that implement AI-driven procedures show their commitment to sustainability and environmental responsibility. These businesses set an example by using all available resources, reducing waste, and saving energy.

This illustrates the possible coexistence of wealth with environmental responsibility. AI-optimized warehouses foster an ethical and ecologically responsible corporate culture that benefits the ecosystem as a whole as well as the bottom line.

The Future Landscape of Warehouse Management

Innovations on the Horizon

As we peer into the future of warehouse management, one of the most groundbreaking innovations lies in the evolution of warehouse management software (WMS). The next generation of WMS, powered by advanced AI algorithms, is poised to revolutionize how warehouses operate.

Imagine a software that not only tracks inventory but anticipates demand patterns, optimizes routes in real-time, and even predicts equipment maintenance needs. Warehouses will be able to make better decisions and respond more swiftly to changing conditions thanks to these intelligent solutions.

A key instrument for handling the complexities of modern logistics, from machine learning to predictive analytics powering inventory management, is the future WMS.

Shaping Business Strategies

Organizations must strategically incorporate warehouse management software advances into their larger business strategy as they redefine operational capabilities. AI-optimized warehouse technology will need to be seamlessly integrated with overarching corporate goals in order to function in the future.

Companies will utilize AI-driven warehouse management to complement their supply chain plans, customer service objectives, and sustainability programs. This strategic alignment ensures that warehouse operations are not isolated but work harmoniously with the entire business ecosystem.

Intelligent companies will employ AI-enabled warehouses as strategic assets that support customer happiness, business resilience overall, and market competitiveness in addition to serving as operational centers.

Successful company strategies in the dynamic environment of the future will be shaped by the capacity to fully use the potential of these technologies and strategically integrate them.

Conclusion

The AI-optimized warehouse ushers in a new era of efficient, sustainable, and responsive operations—it's more than just a logistical boost. Precise inventory management, streamlined processes, and environmentally responsible practices define these AI-powered facilities.

To increase efficiency and accuracy, these facilities employ real-time adaptability, predictive analytics, and machine learning. They promote environmental stewardship by decreasing waste and preserving resources.

Future warehouse management software developments promise much more progress and successful company strategies will be those that strategically use these technologies.

The AI-optimized warehouse, a novel approach to operations management, will transform the logistics sector for years to come.