Hello!

Prototyping is a crucial research and development stage for any product.

It enables businesses to:

It enables businesses to:

- Test product design

- Examine functionality

- Uncover problems

- Receive useful feedback from potential users

- Make modifications

- Discuss manufacturability and related costs

Most enterprises understand the need to invest in prototyping. Product excellence is assured if the best use is made of this stage to problem-solve. However, the research and development stage is costly and very time-consuming. What many businesses actually want to know is what the most effective, efficient and economical way to prototype is.

Most enterprises understand the need to invest in prototyping. Product excellence is assured if the best use is made of this stage to problem-solve. However, the research and development stage is costly and very time-consuming. What many businesses actually want to know is what the most effective, efficient and economical way to prototype is.

Rapid prototyping using 3D printing technology is increasingly becoming popular. Here, we look at some of the important advantages it offers over more traditional methods of prototyping.

Methods of prototyping

Older prototyping methods vary from clay or wooden models to CNC machining. None of these are optimal. They all take a considerable amount of time. They may bear minimal resemblance to the intended look of the product and have limitations in terms of true-to-life testing capabilities.

Rapid prototyping is the newest form of prototyping. It’s more widely available and accessible than ever before. While larger businesses may have the capacity to invest in 3D printing machines and produce their own 3D printed prototypes, smaller and medium-sized enterprises can make use of specialist 3D printing companies.

Rapid prototyping is the newest form of prototyping. It’s more widely available and accessible than ever before. While larger businesses may have the capacity to invest in 3D printing machines and produce their own 3D printed prototypes, smaller and medium-sized enterprises can make use of specialist 3D printing companies.

These services can produce a 3D-printed prototype very quickly, sometimes even with a same-day turnaround.

What is rapid prototyping?

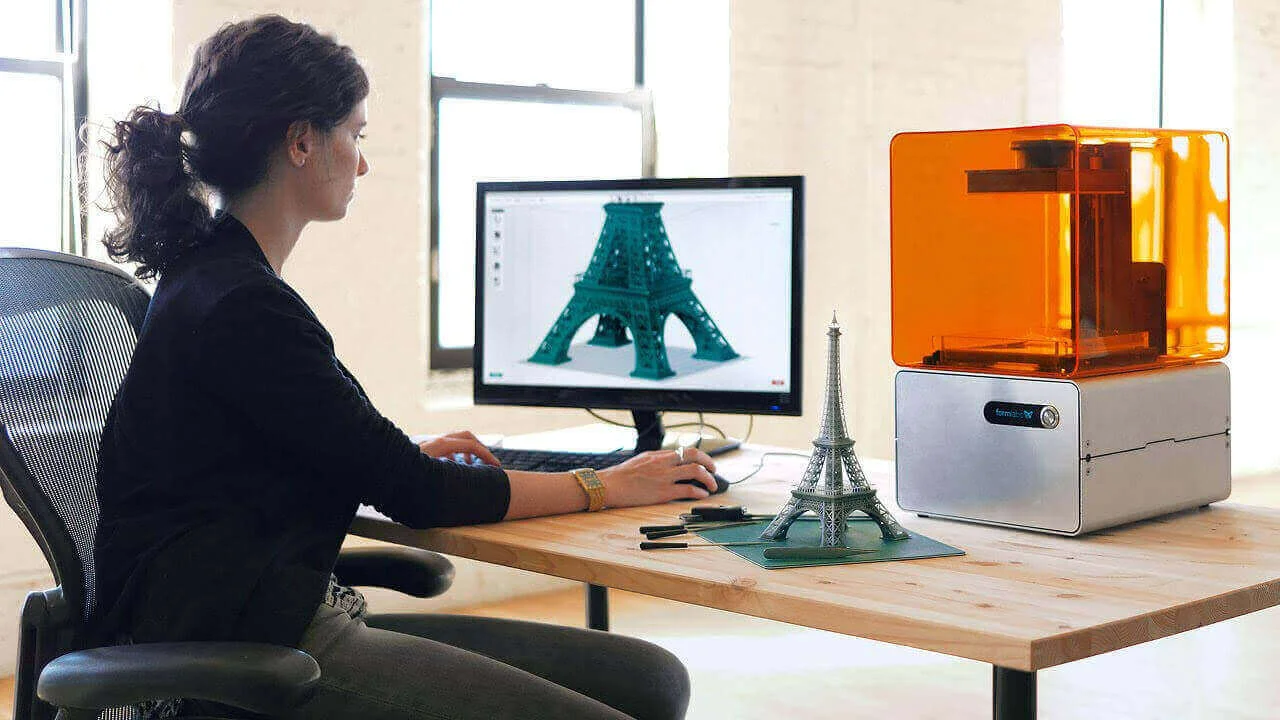

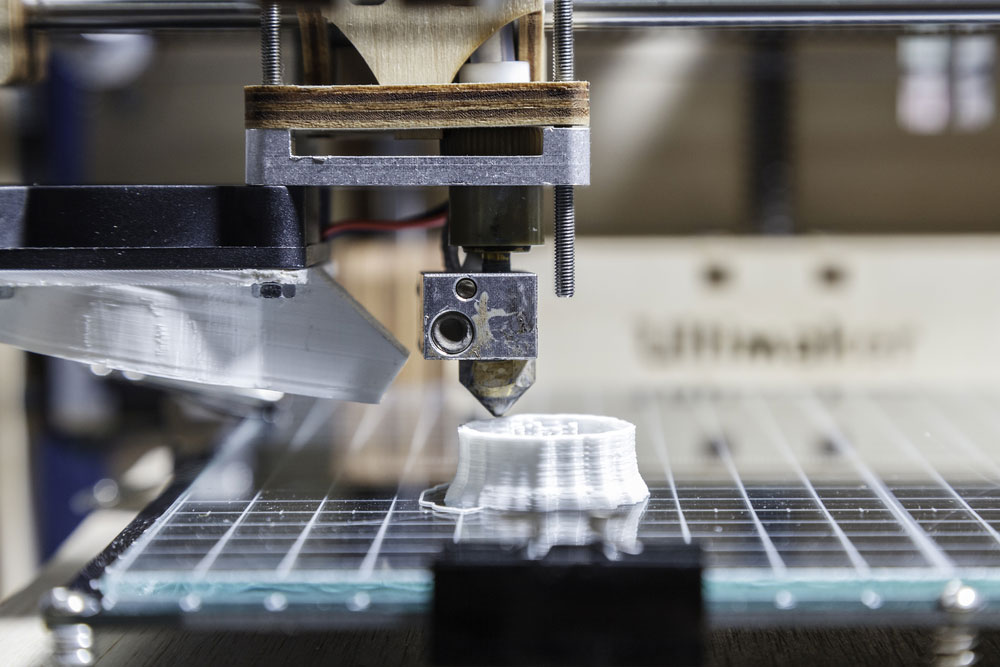

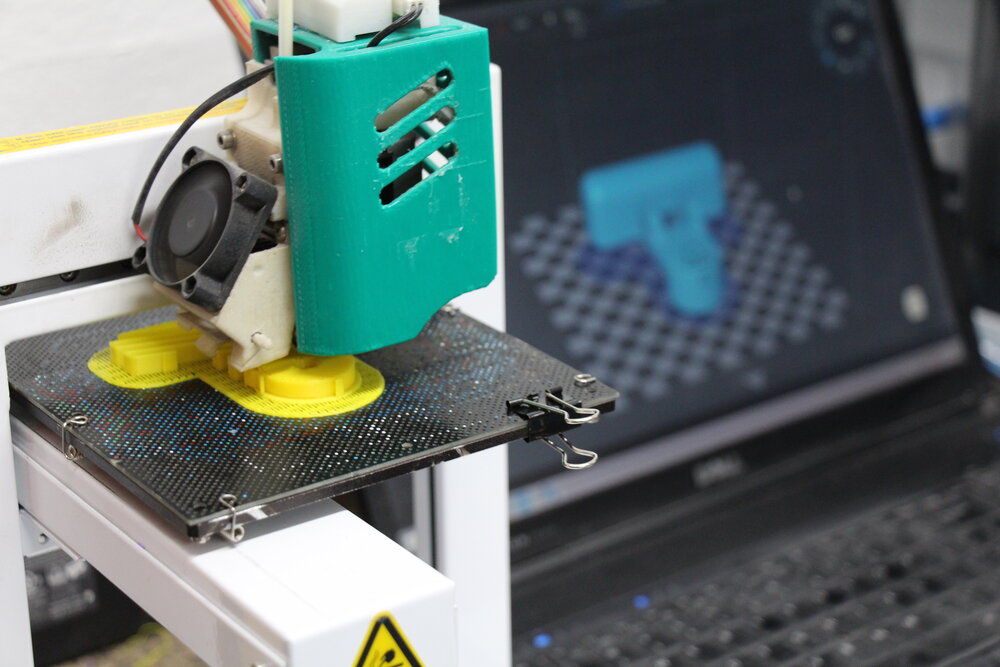

Rapid prototyping is the fast assembly of a prototype using most 3D software packages in conjunction with 3D printing technologies. 3D printing is also known as additive manufacturing. A 3D printer uses data directly from the 3D software to build the design in successive layers of cross-sections.

What are the advantages of using rapid prototyping?

Speed

As already explained, rapid prototyping involves printing 3D parts directly from the 3D software.

This can be done incredibly quickly compared to traditional mocking up. Think hours or days instead of weeks or months. All businesses need to do is to send their design file to their chosen 3D printing service and then choose the materials they wish to have their prototype printed in.

This can be done incredibly quickly compared to traditional mocking up. Think hours or days instead of weeks or months. All businesses need to do is to send their design file to their chosen 3D printing service and then choose the materials they wish to have their prototype printed in.

A company can eliminate time spent producing in-house models and the tools needed to build them.

Rapid prototyping buys your business time that can be used for problem solving, reworking, testing a greater range of materials, and even more stringent finetuning of your design.

Quite simply, a prototyping procedure will detect problems earlier when your company opts to use 3D printing technology, giving you more time to work on them. Alternatively, you’ll get your design into production faster.

Accuracy

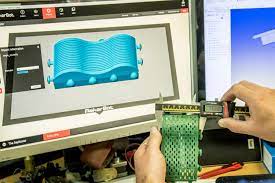

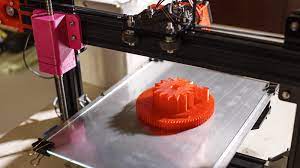

3D printing works by building up very thin layers over and over.

This technique allows your business to create very intricate models. You can choose to print in multiple materials and create a variety of very realistic samples. Rapid prototyping is a very flexible process that can be tweaked on-demand to suit your unique requirements. Any business can easily produce something fully customized.

This technique allows your business to create very intricate models. You can choose to print in multiple materials and create a variety of very realistic samples. Rapid prototyping is a very flexible process that can be tweaked on-demand to suit your unique requirements. Any business can easily produce something fully customized.

While traditional methods of prototyping are limited in terms of an accurate-looking finish, 3D printing can be completed in a myriad of colors and textures.

It is possible for a prototype to look and feel like a real product. This is going to give an enterprise a superior prototype to present to potential clients, customers and investors.

Economy

As with all prototyping, 3D-printed prototypes allow testing of a product before a company makes costly investments in manufacturing and production tooling, helping to save money in the long term.

But 3D printing also has additional cost-saving benefits. One of these is on materials for prototyping. There is very little waste produced during the 3D printing process.

But 3D printing also has additional cost-saving benefits. One of these is on materials for prototyping. There is very little waste produced during the 3D printing process.

Consider the waste produced during other prototyping methods, with offcuts and other unused materials left over. 3D printing offers the chance for your business to save on materials storage and reduce waste and its impact on the environment.

A further cost reduction is that it is no longer necessary to develop novel tools for prototyping or to deploy your staff to use them. Your prototyping will be streamlined to using 3D software and a 3D printing service each and every time. The human involvement in 3D printing is minimal, meaning that 3D printing services are affordable. If you are considering investing in 3D printers for your business, the machine itself is by far the largest expense.

The time saved on the research and development stage will also help your business become more efficient and improve profitability. You can invest the saved time and costs into marketing and product launch, for instance.

Improved feedback

While 3D printing gives your company’s prototype an accurate look and feel, you can go far beyond this.

You can test various materials in real-world environments. A good 3D printing service should offer a wide portfolio of materials. Materials currently available for 3D printing include various plastics, waxes, metals, elastomer, composites, and more.

You can test various materials in real-world environments. A good 3D printing service should offer a wide portfolio of materials. Materials currently available for 3D printing include various plastics, waxes, metals, elastomer, composites, and more.

You can see how these materials perform under the stresses of everyday use. With 3D printing, you are getting a realistic product that can be used for comprehensive initial user testing.

Rapid prototyping is an affordable way to accomplish this. You can get in-depth feedback more quickly.

Lower risk

Finally, the savings in time and costs mean that you are lowering the risks associated with product development. If your design doesn’t work, you have spent less time and money finding this out. Your business will not have invested large amounts in materials and prototyping tools. You can just go straight back to the drawing board.

Finally, the savings in time and costs mean that you are lowering the risks associated with product development. If your design doesn’t work, you have spent less time and money finding this out. Your business will not have invested large amounts in materials and prototyping tools. You can just go straight back to the drawing board.

The high quality associated with rapid prototyping also minimizes the risks of problems being discovered after manufacturing has already begun. Your team will be able to rigorously test a design before you commit to production runs.

Who should be using rapid prototyping?

There is a huge range of applications for rapid prototyping across multiple industries. The automotive and aerospace industries and healthcare innovations are just a few examples of where 3D printed prototypes are frequently used. This is because experience has shown that rapid prototyping is the most cost-effective way to build useful, testable, high-quality prototypes.

There is a huge range of applications for rapid prototyping across multiple industries. The automotive and aerospace industries and healthcare innovations are just a few examples of where 3D printed prototypes are frequently used. This is because experience has shown that rapid prototyping is the most cost-effective way to build useful, testable, high-quality prototypes.

Whatever your business, you should be considering streamlining your research and development phase with 3D printed prototypes.

- Getting Started With PETG Filament 3D Printing

- Benefits of 3D Printing for Manufacturers

- Digital Marketing for Manufacturers

- 5 Tips Manufacturers can take to Combat Cyber Attacks

Thank you!

Subscribe to our newsletter! Join us on social networks!

See you!