Helo!

In just a few years, the roles of loaders, assemblers, packers, and other manual laborers performing low-cost, repetitive tasks will largely vanish. The catalyst? Humanoid robots, led by innovators like Unitree and Tesla’s Optimus, are poised to dominate industries with unprecedented efficiency and scalability.

In just a few years, the roles of loaders, assemblers, packers, and other manual laborers performing low-cost, repetitive tasks will largely vanish. The catalyst? Humanoid robots, led by innovators like Unitree and Tesla’s Optimus, are poised to dominate industries with unprecedented efficiency and scalability.

As Unitree gears up to broadcast robot combat demonstrations in about a month—showcasing robots controlled via motion capture, controllers, or voice commands—the future of work is coming into sharp focus.

The Robot Revolution

The rapid decline of manual labor jobs is no longer a distant prophecy. Automation has already transformed industries, but the next wave—affordable, mass-produced humanoid robots—will be a game-changer.

The rapid decline of manual labor jobs is no longer a distant prophecy. Automation has already transformed industries, but the next wave—affordable, mass-produced humanoid robots—will be a game-changer.

With production costs potentially dropping to $300-$500 per unit, these robots will become viable for industrial buyers, particularly as logistics and processes are optimized. Unlike human workers, robots require no salaries, unions, breaks, or benefits.

They operate 24/7 without vacations, training, or complaints about workplace conditions. They don’t need lighting, ventilation, toilets, cafeterias, or parking lots. They don’t steal, err, or strike.

What sets these robots apart is their adaptability. A robot’s capabilities are 90% software-driven, meaning they can be updated multiple times daily with AI-generated improvements.

What sets these robots apart is their adaptability. A robot’s capabilities are 90% software-driven, meaning they can be updated multiple times daily with AI-generated improvements.

Drawing data from every deployed unit, artificial intelligence will enable robots to learn continuously, mastering new skills in real-time.

Need a robot for a specialized task? It can autonomously swap tools—like a chef changing kitchen attachments—and get to work. This flexibility eliminates the need for retraining or team-building exercises.

Also read: https://quasa.io/media/experts-estimate-that-by-2033-robots-will-do-39-of-household-chores-unlikely

The Economic Shift

The implications extend far beyond individual jobs. Cheap labor markets in Asia, where workers earn as little as $1 per hour, will lose their edge as robotic production becomes more cost-effective.

Industrial companies will initially purchase robots, but soon, leasing models with minimal upfront costs will dominate, making adoption even easier. Within 4-5 years, robots could claim 99% of the manual labor market, rendering concerns about skilled labor shortages—like those voiced by Apple’s Tim Cook—obsolete.

Industrial companies will initially purchase robots, but soon, leasing models with minimal upfront costs will dominate, making adoption even easier. Within 4-5 years, robots could claim 99% of the manual labor market, rendering concerns about skilled labor shortages—like those voiced by Apple’s Tim Cook—obsolete.

This shift will disrupt global manufacturing. Why maintain factories in China, India, or Africa when robots enable compact, efficient production closer to consumer markets?

A factory half the size of today’s, filled with robots, can operate anywhere—slashing costs and bypassing import tariffs.

For the U.S., high tariffs on foreign goods and incentives for robotic production could spark a manufacturing renaissance, relegating other nations to R&D hubs rather than production centers.

- Robodog Runs Full Marathon

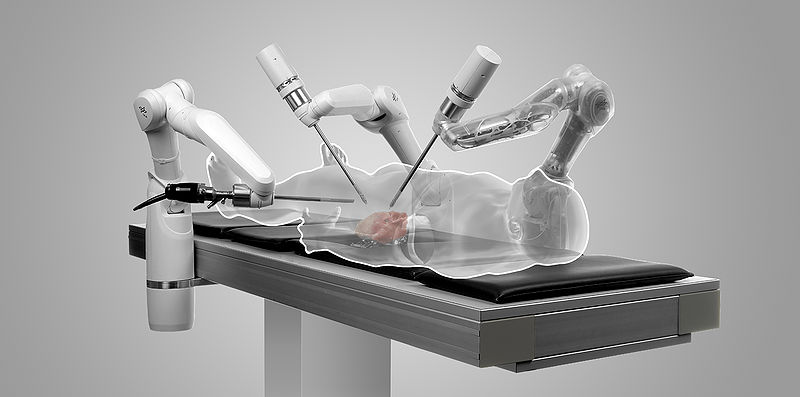

- Robot Performs First Ever Fully Autonomous Dental Surgery on Live Patient

- Robot Plays Cello With Live Orchestra

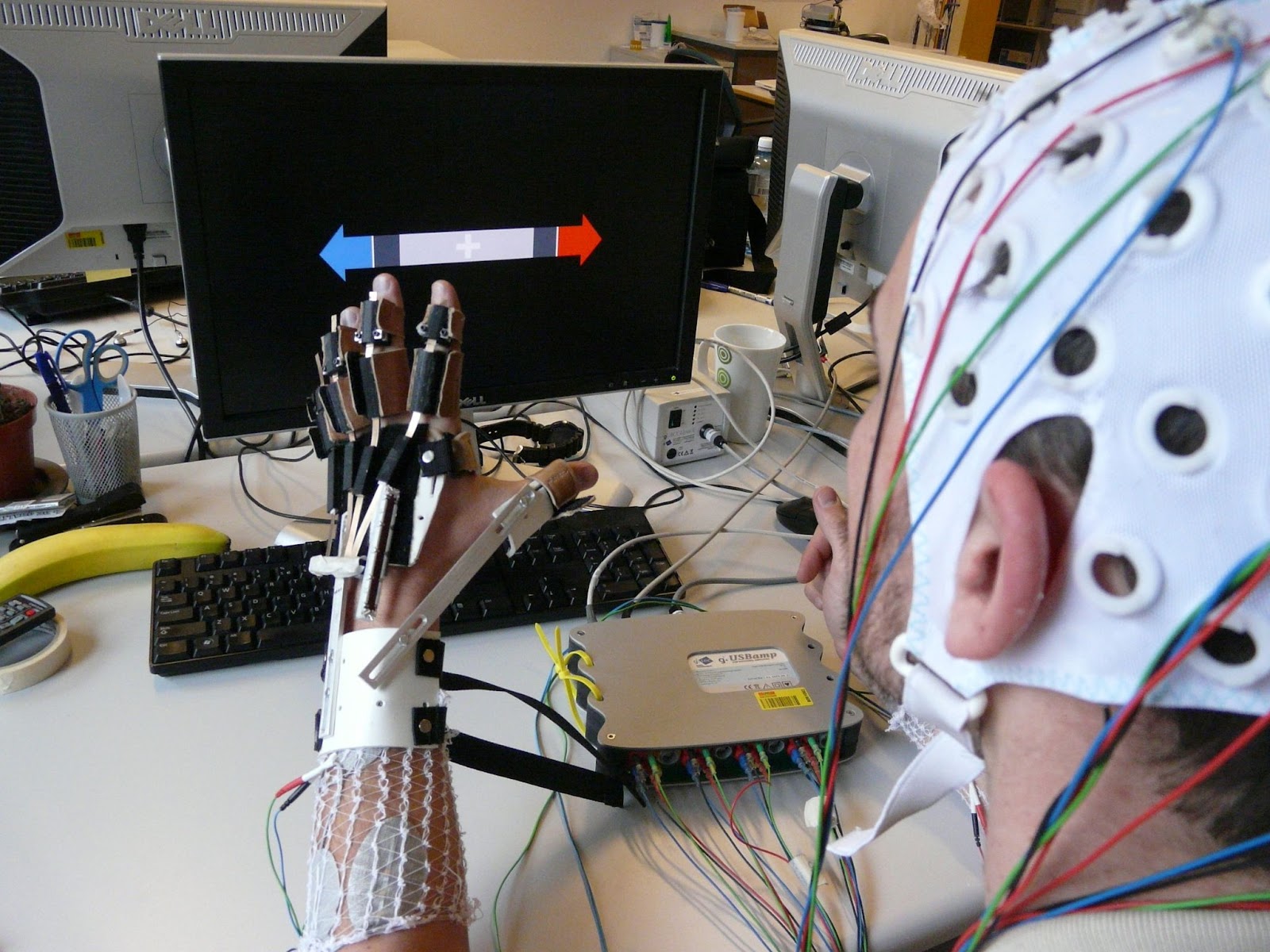

- Neuralink Testing Robot Arm Controlled by Brain Chip

The Market and Its Players

The humanoid robot market, potentially worth $1 trillion, is heating up. Unitree and Tesla’s Optimus are early leaders, but others—automakers, tech giants, and startups—will likely join the race.

This growth aligns with four key trends driving the future economy:

This growth aligns with four key trends driving the future economy:

- Energy development to power AI data centers.

- Data centers for processing vast amounts of information.

- Chip production for AI and robotics.

- AI advancement, from general-purpose models to specialized systems embedded in robots and IoT devices.

- Robotics and drones for every conceivable application.

These sectors will demand trillions in investment, with investors choosing between powerhouses like the U.S. and China. The outcome will shape global economic dominance.

The Human Cost

For workers, the transition will be brutal. Manual laborers, often without advanced skills, face obsolescence as robots take over. Retraining programs may help, but many will struggle to pivot to tech-driven roles. Entire communities built around factories and warehouses risk economic collapse as jobs vanish. The social safety net—already strained—will face unprecedented pressure.

For workers, the transition will be brutal. Manual laborers, often without advanced skills, face obsolescence as robots take over. Retraining programs may help, but many will struggle to pivot to tech-driven roles. Entire communities built around factories and warehouses risk economic collapse as jobs vanish. The social safety net—already strained—will face unprecedented pressure.

Yet, there’s hope for those who adapt. The future will split humanity into two groups: those who leverage AI to amplify their skills and those left hoping for universal basic income. Governments and industries must invest in education and reskilling to bridge this gap, ensuring workers aren’t abandoned in the rush to automation.

A New Era

The rise of humanoid robots marks the end of manual labor as we know it. Unitree’s upcoming robot battles are just a glimpse of what’s to come—versatile, tireless machines that redefine efficiency.

The rise of humanoid robots marks the end of manual labor as we know it. Unitree’s upcoming robot battles are just a glimpse of what’s to come—versatile, tireless machines that redefine efficiency.

While they promise economic gains and technological marvels, they also challenge us to rethink work, equity, and opportunity. In 4-5 years, the world will look very different.

The question is whether we’ll build a future that benefits all or one that leaves most behind.

Thank you!

Join us on social media!

See you!